The Effects on Quality

As a mustard producer, the care you take in the harvest, handling and storage of your crop will seriously affect quality. Quality, in many cases, is as important as yield when considering net return. Mustard processors and buyers have strict quality requirements for several factors, many of which can be controlled to some degree.

Mustard Quality

Canadian Grain Commission has established standards for mustard quality. In order to produce a high-quality crop, mustard producers need to understand the factors that can lead to downgrading a mustard crop.

The Canadian Grain Commission has tables that outline these factors and their associated tolerance levels.

Green seed

All immature mustard seed contains the green pigment chlorophyll, which can impart an off colour on finished products. With the right environmental conditions, chlorophyll will dissipate before harvest, but not after. Three enzymes remove chlorophyll from the seed as part of the natural maturing process. These enzymes are active only if the moisture level of the seed is above 20 per cent, and the ambient temperature is above 5ºC. Frost prior to harvest or severe heat after swathing can both destroy the enzymes and result in the green colour being locked in the seed. Green seed will not diminish in the bin. In order for it to reduce, seed must be in either the windrow or the standing plant.

Heated seed

Excess moisture and/or high temperature in stored mustard seed may lead to heating. Mustard must be stored with lower moisture content than cereal grains because of mustard's high oil content. The high oil content means that any moisture in the seed is concentrated in the meal fraction. As an overall percentage, the moisture content can appear low but may cause problems because it is concentrated in only half of the seed. Mustard intended for long-term storage should be kept at less than nine per cent moisture and less than 18ºC. This moisture and temperature regimen inhibits mould growth, insect feeding and general seed deterioration. After binning, mustard will go through a sweating period caused by respiration. Mustard seed is alive and, like all living organisms, it respires or takes in oxygen and releases carbon dioxide. This process generates heat and moisture, and generally elevates the moisture content of the newly binned mustard seed by one per cent.

Sclerotinia sclerotia

Sclerotinia is a disease of mustard, canola, sunflower, flax, pulse crops and many weed species. Severe infestations require high humidity and consequently, sclerotinia does not generally cause mustard producers significant yield loss. The disease produces hard black resting bodies, called sclerotia, in the stems of infected plants, which, if threshed out during harvest, can end up in the seed sample. Even very low levels of infestation can lead to downgrading.

Ergot

Ergot is a cereal disease that does not infect mustard; however, the disease is similar to sclerotinia in that the resting stage is sclerotia. Ergot contamination would most likely result from infected volunteer cereals or contaminated harvesting, transportation or storage facilities. Because ergot sclerotia contain a neurotoxin, the tolerance is very low.

Excreta

Excreta are the droppings of rodents and insects. Contamination is usually due to unclean harvest, storage or transportation equipment. As well, inadequate storage facilities that allow access to rodents may lead to problems. Good quality mustard seed has essentially no tolerance for excreta.

Rime

Mucilage is the substance that surrounds the seed coat of yellow mustard. It gives mustard many of its desirable qualities, namely its water binding properties. Repeated wetting and drying of the seed causes this mucilage to flake off and cover the seed in a white coating known as rime. The Canadian Grain Commission does not grade rime, but it is a downgrading factor at the buyer and processor level.

Swathing versus straight combining

For high-quality mustard, straight combining is the preferred option. However, as some of the following factors indicate, swathing may still be necessary. When deciding to swath or straight combine, producers must consider the following: mustard type, the evenness and stage of maturity and crop height.

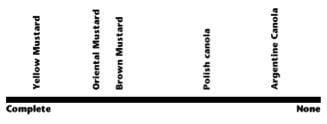

Yellow is the most shatter-resistant of all mustard types. Beyond that, the most shatter-resistant types are oriental mustard, brown mustard, Polish canola and Argentine canola (in declining order). Canola was added as a reference point: Argentine canola has very little shatter-resistance and is generally swathed.

Evenness refers to the range of relative maturity among plants. In many fields, some areas may mature earlier than others will, especially high growth areas in low-lying spots, . Producers can force these fields to ripen consistently by swathing. If producers have uneven maturity in their mustard crops and wait until all plants are mature enough to straight combine, they run the risk of increased shattering. At the same time, straight combining too early will increase green seed numbers and elevate moisture content.

The stage of maturity affects swathing. Producers are better off straight combining over-ripe mustard because swathing can cause shattering. Maturity can change very quickly in hot dry conditions and the crop needs to be closely monitored prior to swathing.

Crop height should also be taken into consideration when swathing. Ensure that the cut is made high enough to adequately anchor the windrow in the remaining stubble, but not so low that the pick-up reel gathers stones and soil.

If you have made the decision to swath, you must consider the stage of maturity, cutting height and anchoring the swath.

Time of Swathing

The most important decision related to swathing mustard is when to begin. Timing will affect yield, quality and net return. For all types of mustard, swathing should begin when the majority of seeds are at less than 25 per cent moisture. At this point, seeds will feel firm when pressed between the thumb and forefinger. Some pods will have developed a purple tinge; lower pods will have changed colour but the upper pods will remain green. Break open several pods along the main stem of the plant. For yellow and oriental mustard, 75 per cent of the seeds will have some yellow colour; for brown mustard, 60 per cent of the seeds will have some reddish-brown colour. Be sure to crack the pods and look at the seed inside; do not decide when to swath solely based on pod colour change. Varieties mature differently. In some, the pod will change colour before the seeds; in others, the reverse occurs.

When swathing, mustard should be cut just below the level of the lowest pods. In most cases, this should leave ample stubble in which to anchor the windrow. Anchoring the windrow is crucial to prevent the swath from blowing. To ensure the windrow is properly anchored, roll and pack the windrow into the remaining stubble. Set the roller so that the windrow is firmly packed, but take care not to shatter overripe pods or pack the windrow so tightly that it cannot properly dry.

Swathing means the crop will need time to cure (the maturing process that reduces moisture content and green seed). If the green seed count is unacceptable at harvest, the only thing that will lower it is time in the swath. In order to reduce green seed numbers, the moisture content in the crop must be above 20 per cent and the ambient temperature must be above 5ºC. Extreme heat shortly after or during swathing, or a frost just before or after swathing, can fix green seed content. Green seed will not clear out in the bin.

Straight combining

Mustard that is uniformly mature and has a low green seed count can be straight combined. Straight combining could also be considered if the crop is too short to properly anchor the windrow. Set the reel speed approximately the same as the ground speed. This will help prevent shattering. The cutter height should be just below the lowest pods in order to minimize the amount of stem that is processed through the combine.

Remember that long-term safe storage requires a moisture content of less than nine per cent and that the moisture level of mustard generally increases by one per cent after binning. In addition, green seed will not cure out after harvest, but it will reduce in the plant if the moisture content is above 20 per cent and the ambient temperature is above 5ºC. Once the crop is harvested, the green seed content is fixed.

Combining

Combine mustard when the moisture content has dropped to around nine per cent, and when most seeds are mature and have an acceptable green seed count. After harvest, green seeds will not significantly cure.

Depending on crop conditions, cylinder speed should be about one-half to two-thirds of that used for cereals. Reduce the cylinder speed to between 400 and 800 rpm, or to the point where the amount of cracked seeds is acceptable. Over-threshing at the cylinder and concave is a common problem when harvesting mustard, causing cracked seeds, high dockage and loading of the shoe with excessive amounts of broken stems and pods. Set the concave clearance to give as good threshing as possible. This will keep the number of unthreshed and broken stems and pods to a minimum. Concave clearance should be wider at the front, up to 25 mm (one inch) and narrower, three to 13 mm (1/8 -1/2 inch) at the back.

Compared to cereals, the cleaning action for mustard depends more on shaking separation than on wind separation. Set the fan speed to approximately three-quarters of that used for wheat. Air volume should be just enough to keep material moving evenly across the sieves. Increase the speed of the shaker shoe by an additional 10 per cent if possible.

The top sieve, or chaffer, setting should be six mm to 10 mm (1/4 - 1/3 in) and the lower sieve setting three to six mm (1/8 -1/4 inch). Excessive trash in the hopper means the sieves are open too much. Alternately, if the sample is perfectly clean, the sieves should be opened slightly. If the returns are too high, there may not be enough wind, the top sieve may be open too much or the cylinder and concave may be over-threshing.

Aeration

The purpose of aeration is to change the temperature of stored grain, not to reduce the moisture content, even though it will be lowered by one or two per cent. If required, aeration should begin as soon as the mustard enters the bin, and should continue until the mustard is near the average outside temperature. When the outside temperature has dropped by 5 to 10ºC, cool the mustard again.

Drying

If the mustard needs to be dried for safe storage, do not exceed 65ºC (150ºF) air temperature and 45ºC (113ºF) seed temperature. Also, remember that mustard seed is denser than cereal seed and it takes two to three times more static pressure to force the air through the crop.

Mustard Quality Reference Guide

| Quality Factor | Management Factor | Suggested Practice |

| Green Seed | Planting | Uniform planting depth and even distribution within the seedbed will lead to even germination and ultimately affect maturity. This makes judging the appropriate time of swathing or straight combining easier and may reduce green seed. |

| Date of Seeding | Early seeding will help to mature the crop before fall frosts. Frost during maturity can permanently destroy the enzymes required to clear the green colour from the seed. | |

| Swathing | If swathing, begin when the mustard seeds have approximately 25 per cent moisture. They will feel firm when pressed between the thumb and finger. For oriental mustard, approximately 75 per cent of the seeds will have some yellowish colouring; for brown mustard, 60 per cent of the seeds will have some reddish-brown colouring. Seed will cure in the swath, and the green colour will dissipate only if the moisture level in the seed remains above 20 per cent and the temperature above 5ºC. | |

| Straight combining | Straight combing is an effective way to reduce green seed, as plants are allowed to cure naturally. However, be sure that all green seed has cured out before straight combining. It will not cure once in the bin. | |

| Rime | Straight combining | Repeated wetting and drying of the seed causes rime. It can occur in the standing plant, but more likely in the windrow. If you have experienced rime in the past, you may want to try straight combining. |

| Excreta | Storage | Ensure that you have thoroughly cleaned the storage facilities and that they are not accessible to rodents. |

| Harvest | Ensure that you have thoroughly cleaned the harvest equipment. | |

| Transportation | Ensure that you have thoroughly cleaned the transportation vessels and that they are not accessible to rodents. | |

| Sclerotinia sclerotia | Weed control | Several mustard-related weeds are susceptible to sclerotinia. Ensure you control them in mustard and preceding crops. |

| Crop rotation | Mustard and several other broadleaf crops are susceptible to sclerotinia. Follow a sound crop rotation that disrupts disease cycles. | |

| Seed source | Ensure that your seed source is free from Sclerotinia sclerotia. | |

| Ergot sclerotia | Weed and volunteer cereal control | Some cereals are susceptible to ergot infection. Ensure that you control all volunteer cereals if ergot has been a problem in the past. |

| Storage | Ensure that you have thoroughly cleaned the storage facilities. | |

| Transportation | Ensure that you have thoroughly cleaned the transportation vessels. | |

| Degree of soundness | Planting | Uniform planting depth and even distribution within the seedbed will lead to even germination and eventually affect maturity. Harvested at the correct time, healthy mustard has a good opportunity to be well matured, sweet and have good natural colour. |

| Fertility | Adequate fertility throughout the growing season will help with proper seedfill, leading to plump, well-rounded seeds. Nitrogen and sulphur are especially important nutrients. Ensure adequate levels of each are available throughout the growing season. | |

| Swathing | If swathing, begin when the mustard seeds contain approximately 25 per cent moisture. They will feel firm when pressed between the thumb and finger. For yellow and oriental mustard, approximately 75 per cent of the seeds will have some yellowish colouring; for brown mustard, 60 per cent of the seeds will have some reddish-brown colouring. | |

| Straight combining | If drying facilities are not available, straight combine when the moisture content is below nine per cent. This allows the seeds to fully mature in the pods, and is an effective way to ensure a high degree of soundness. | |

| Wild mustard, canola / rapeseed | Crop rotation | The best method to avoid contamination of mustard with canola is to never plant them on the same piece of land. If this is not possible, allow a minimum of four years between Argentine canola and mustard, and six years between Polish canola and mustard. Ensure that you control all wild mustard and volunteer canola plants in the crops preceding mustard. |

| Seed source | At time of purchase, inspect the seed tag, or have your saved seed analysed for wild mustard and/or canola admixtures. Do not plant mustard seed with either wild mustard or canola seed contamination. | |

| Soft earth pellets / stones | Straight Combining | A combine may pick up soft earth pellets and stones in a windrow. If the crop is short and you must swath near the soil surface, you may be better off to straight combine. |

| Storage | You must clean storage facilities and ensure they are free of soft earth pellets and stones. | |

| Heated Seed | Harvest | If possible, harvest mustard below 10 per cent moisture for short-term storage (less than five months), and below nine per cent moisture for longer-term storage (beyond five months). |

| Deflector | When auguring into the bin, use a deflector to evenly spread heavier, moist green material and fines away from the core. This will help reduce the chance of hot spots developing., as moisture in the green material can initiate hotspots. | |

| Aeration | Aeration will reduce the temperature of stored seed. This will inhibit the growth of mould and reduce spoilage. Mustard stored for a long period should be kept at less than 18ºC. | |

| Drying | Mustard stored for a long period should be kept below nine per cent moisture. When drying mustard seed, do not exceed 65ºC (150ºF) air temperature and 45ºC (113ºF) seed temperature. |